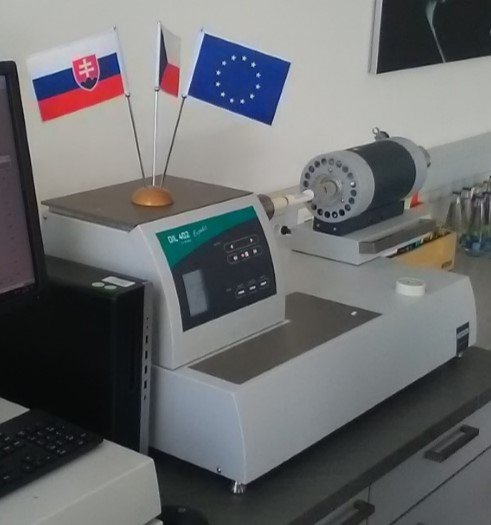

Modernization of laboratory equipment of GLASS CENTRE at Secondary art-industrial glass school Valašské Meziříčí - measurement of thermal expansion of glass for industrial enterprises and the public.

Secondary School of Arts and Crafts in Valašské Meziříčí develops applied research on glass materials. Within this activity, the purchase of a dilatometer for measuring the coefficient of thermal expansion of existing and newly developed glasses for industrial and artistic activities was realized.

Specifications of the dilatometer:

Producer: company NETZSCH-Gerätebau GmbH Selb

Type: DIL 402 CL Expedis

Furnace parameters:

- heating speed0.001 K/min … 50 K/min

- temperature accuracy 0.1 K

- resolution of temperature reading 0.001 K

- temperature stability isothermal ± 0.02 K

Measurement parameters and instrument parameters:

- automatic measurement of sample length with an accuracy of 0.01 mm under predefined clamping forces

- automatic optimal sample settling function

- maximum sample length 52 mm

- maximum sample diameter 8 mm

- measurement range 10000 µm (±5000 µm)

- resolution ΔL 2 nm over the entire measuring range 10 mm

- repeatability of measurements ΔL/L0,002%

- measurement accuracy ΔL/L0 0,003%

- pressure contact force detection and control 10 mN to 3N during measurement

- gas-tight instrument design

Software:

- measurement software for programming the experiment with the possibility of changing the program during the measurement

- expert software Proteus 8.02 for data evaluation with the possibility of continuous evaluation of the running experiment without interruption

- temperature calibration using phase transformation standards

- automatic detection of the sample softening point - prevents damage to the instrument if it is exceeded

+420 571 612 420

+420 571 612 420 gds@gds.cz

gds@gds.cz

EN

EN

CZ

CZ

hu

hu

bg

bg

Settings

Settings