Bonding of coloured glass used to be very difficult or virtually impossible, mainly due to problems with curing of UV adhesives. A partial solution was offered by Loxeal UV 30-21 adhesive with higher sensitivity to UV light, but it was still not sufficient for most coloured glass.

Now comes a new product, Loxeal UV 30-42 adhesive, which cures with minimal light exposure and even in normal daylight. This enables reliable bonding not only of tinted transparent glass, but also of laminated glass with embedded films.

The main advantages of the new Loxeal UV 30-42 adhesive

- Designed for bonding coloured glass and metals

- Excellent adhesion to PC, PVC and other plastics

- Not sticky after curing

- Extremely fast curing (365-420 nm, even at low intensity)

- Cures also under visible light (approx. 470 nm)

- Excellent resistance at 85 °C / 85 % relative humidity

- High flexibility

- Transparent bond with resistance to yellowing

- Thixotropic properties for easier application

Comparison of Loxeal UV 30-42 with similar adhesives

Other adhesive innovations

AC5480 - A thixotropic, flexible two-component adhesive with low odour. Offers high resistance to moisture and oil.

Loxeal UV 30-16 - A new adhesive for bonding glass to plastics. A modern replacement for UV 30-12 - higher strength, anti-yellowing additives and great results even on problematic plastics such as PMMA and ABS.

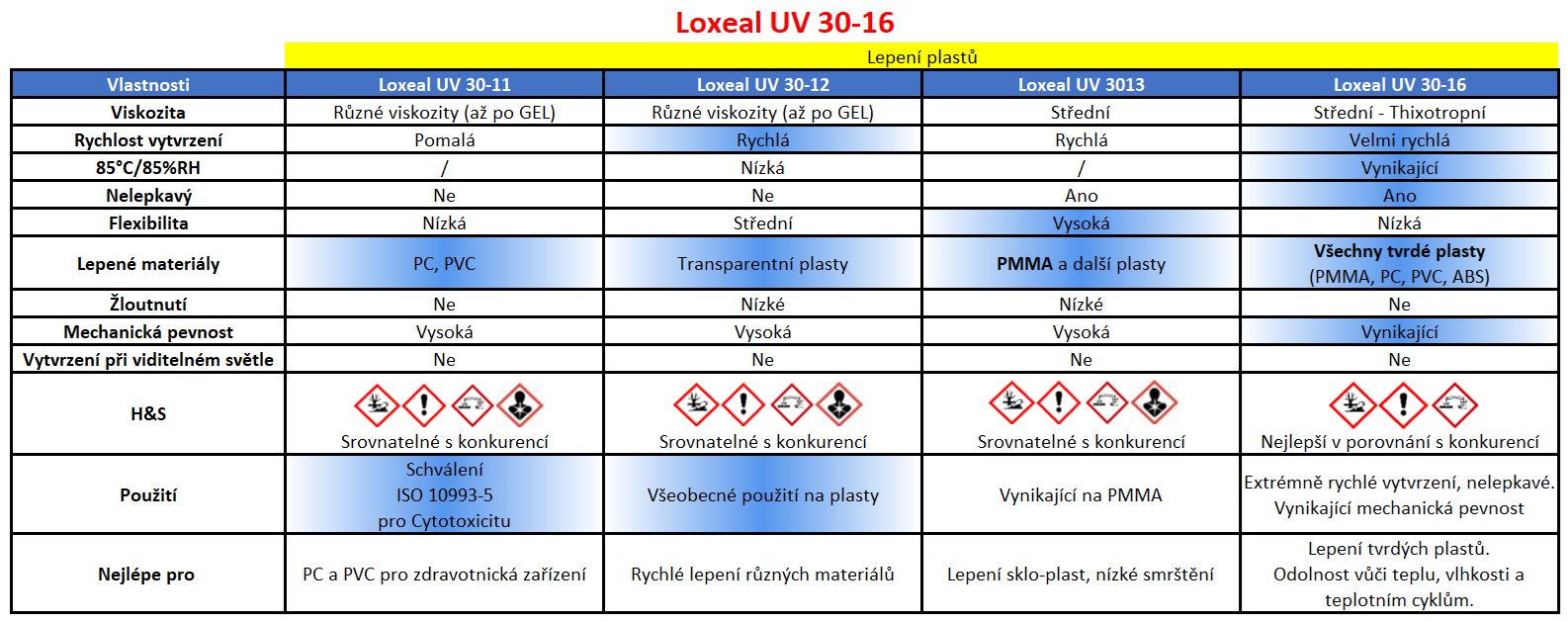

Comparison of Loxeal UV 30-16 with similar adhesives

Read also articles from our series on UV adhesives

Preparing glass surfaces before bonding

Tips for flawless UV adhesive application when bonding glass

Curing UV adhesives: what influences curing time and bond strength

Typical joints when bonding with UV adhesives

Would you like to know more about UV adhesives? Then attend our popular glass bonding seminar.

Article written by:

Martin Valášek

Flat glass, paints, UV adhesives

technical support, blasting systems

+420 571 612 420

+420 571 612 420 gds@gds.cz

gds@gds.cz

EN

EN

CZ

CZ

hu

hu

bg

bg

ro

ro

Settings

Settings