Rollmac's top-of-the-range rollercoaters significantly reduce ink consumption when printing on glass, reduce cleaning times to a minimum and allow precise adjustment of ink application height. Thanks to unique technologies such as reverse roller rotation or interchangeable rubber sleeves, they offerRollmac offers a solution for efficient printing of flat glass and design decoration, including frame printing and sandblasting.

What makes Rollmac rollercoaters so unique?

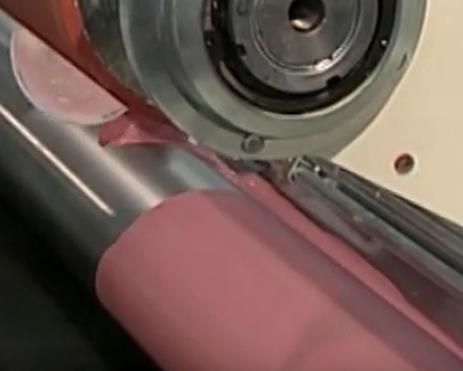

1. Unique single roller and pressure knife system

Reduces the amount of ink needed to start printing and consequently the ink wasted in cleaning - for competitor machines we are talking about higher kilos of ink, for Rollmac machines about 0.2 - 0.8 kg of ink (depending on the width of the model).

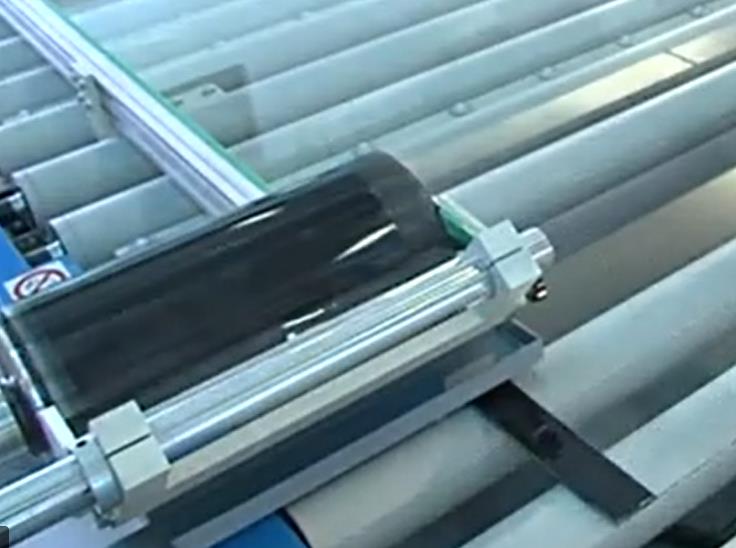

2. Variability of application height

Thanks to the reverse rotation of the roller (against the movement of the glass), the height of the paint layer can be varied on Rollmac machines by changing the speed of the roller or the glass on the belt. With conventional rollcoaters, the height of the application is precisely determined by the depth of the roller tread and cannot be changed.

3. Optional roller surface

The rollers on Rollmac machines can be fitted with a rubber surface (coating system - suitable for glass 2 - 25 mm with various bends and unevennesses - e.g. from hardening), or an all-metal version for printing glass 2 - 8 mm. The surface is formed by miniature pyramids or cones without vertices.

4. Cleaning speed

Unlike commonly available solutions, Rollmac rollercoaters are unique and do not require tens of minutes or even hours to clean the machine of used ink. Thanks to the automatic cleaning system (or fast manual cleaning), it is ready for the next use in approximately 10 minutes.

5. Overprinting capability

Thanks to the reverse rotation of the roller on Rollmac machines (against the direction of glass movement), by simply lifting the roller and returningby simply pushing the glass in front of it, the old layer of wet ink can be removed and a new one printed at the same time - without any washing, in about one minute.

With other commonly used systems, on the other hand, the glass must first be cleaned, washed and re-founded, which is a considerably more demanding operation - both in terms of time (tens of minutes) and handling (requiring staff and space). In addition, all washed paint ends up as waste.

6. Coating system

With the Rollmac system, the metal core can be reused and only the rubber sleeves can be changed, thus increasing theThe Rollmall also reduces the cost of rollers and shipping by sending only a lightweight rubber sleeve instead of the entire metal roller.

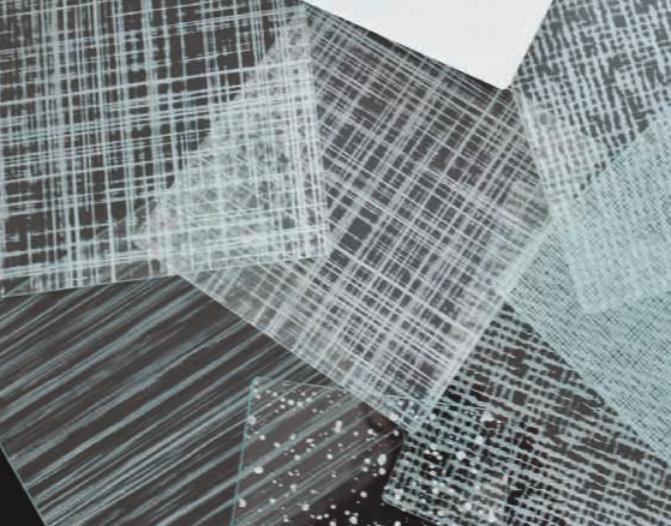

7. Reversible operation for design decorations

Thanks to the unique possibility of reverse and synchronous rotation of the roller (against the movement of the glass and in the direction of movement), by changing the rubber cylinder sleeve with a design pattern and switching to synchro mode to apply this decoration to the glass , or ETCH EFFECT.

The need to change the roller can be eliminated by acquiring a three-roller ROLLMAC MULTIGLASS model and the roller can always be changed just by turning it.

7. GLASSLINE - rollercoaters for printing stripes and frames

This specific type of rollercoater can apply paint along the edge of the glass in widths from 5 to 300 mm. After coating one side, the glass can be rotated (automatically or manually), returned to the start and the next side can be printed - until the entire frame is formed. Handling is very easy, especially with larger glass formats. In addition, the ROLLMAC system is approved for the use of TEA BLACK ink for direct printing on the plated layer.

For more information also visit: https://www.gds.cz/en/en/c-rollercoatery, https://www.rollmac.it/a_17_EN_16_1.html

Article written by:

Martin Valášek

Flat glass, paints, UV adhesives

technical support, blasting systems

+420 571 612 420

+420 571 612 420 gds@gds.cz

gds@gds.cz

EN

EN

CZ

CZ

hu

hu

bg

bg

fr

fr

ro

ro

Settings

Settings