So, what does an ideally equipped spray shop look like and what shouldn't be missing from it?

LOCATION:

It's important to remember that spray decorating is a process prone to dust or requiring a clean environment. Therefore, already when choosing the location of the decoration operation, think about the possible collision with dusty operations (e.g. sandblasting workshop). Conversely, downstream technologies, such as drying (firing) kilns, should be as close as possible to, or even part of, the decoration workshop.

You will need compressed air to operate the spray shop. Thus a compressor, which is a source of noise. It is therefore ideal to locate the compressor in another part of the building and bring the air in through ducting. Of course, you should install a dehumidifier in the air distribution system and ideally also integrate an air dryer (de-icing unit).

The choice of a suitable location is also influenced by the question of the air handling system. Spray boxes need to be exhausted. The boxes have their own fans, but the extraction of the exhausted air to the outside is very individual in relation to the chosenlocation (the longer the ductwork, the higher the purchase cost).

It is also necessary to take into account the need to bring a quantity of air into the spray shop that corresponds to the amount of air extracted. ATTENTION! In the winter months, the supply air must be heated. This can be done e.g. with a gas or electric heater. If you run a heat generating plant (e.g. a glassworks), you can use this heat. Be sure to remove dust impurities from the incoming air.

The requirements for the spray shop are also influenced by the type (and size) of product to be sprayed and the volumes to be sprayed (piece, small batch or large batch production).

SPRAY SHOP ZONES:

A spray shop can be divided into the following zones:

Zone 1.) PAINT STORAGE

Zone 2.) PAINT PREPARATION

Zone 3.) GLASS PREPARATION

Zone 4.) SHRINKING

Zone 5.) DRYING (FIRING)

Zone 6.) CONTROL, PACKING (or preparation for further decoration)

Ad 1.) PAINT STORAGE

The paint store should meet the conditions as specified in the TL of the paint used. This is usually a condition related to temperature. Also consult your safety engineer when selecting and arranging the paint store. He will certainly be interested in the quantity and nature of the paints you will be storing.

Ad 2.) PAINT PREPARATION

Scales - when selecting a scale, you will want to consider its maximum weighing capacity (i.e. what maximum amount of paint you will want to prepare) and its accuracy. Accuracy requirements will vary depending on whether you will be working with ready-made paints or whether you want to mix the shades yourself. If you will be mixing your own, it also depends on whether you will be mixing from already prepared base colours or from base coat and pigment concentrates. In this case you will need very accurate scales.

Mixers - the paint needs to be mixed before use. Plastic or stainless steel spatulas will be a good help. However, for thorough mixing we recommend machine mixing. You can use one of the professional mixers, but you can also achieve a good result by using a drill with a suitable mixing attachment.

You will need various tools to prepare the paints. For example, cups, containers, spatulas, pipettes. For measuring viscosity, a Ford cup or an electronic viscosity meter. etc.

Ad 3.) GLASS PREPARATION

The glass must be clean. Clean means free of dust and dirt, but also of any grease. When decorating container glass, make sure it has been treated with Hot-End-Coating or Cold-End-Coating (common for container glass). If so, be sure to test the paint adhesion first. You may need to flame-burn the glass.

Depending on the nature and quantity of the decorated products, different cleaning methods can be chosen. Different glass cleaners, non-woven cloths.

Flame searing helps a lot not only by burning off dust particles, but also by preparing the glass surface for better adhesion of organic paints. If you equip the flame sear with a mixer for the silane admixture, you have done the maximum for the pre-treatment of the glass before decoration.

Note: the glass should ideally be tempered to operating temperature before decoration. Therefore, if it is stored in cold weather in unheated warehouses, allow for the time required to heat the glass.

Ad 4.) SHRINKING

We have already discussed the need to ensure absolutely dust-free operation. In the most modern plants, spray shops are designed as pressurized rooms and clean rooms.

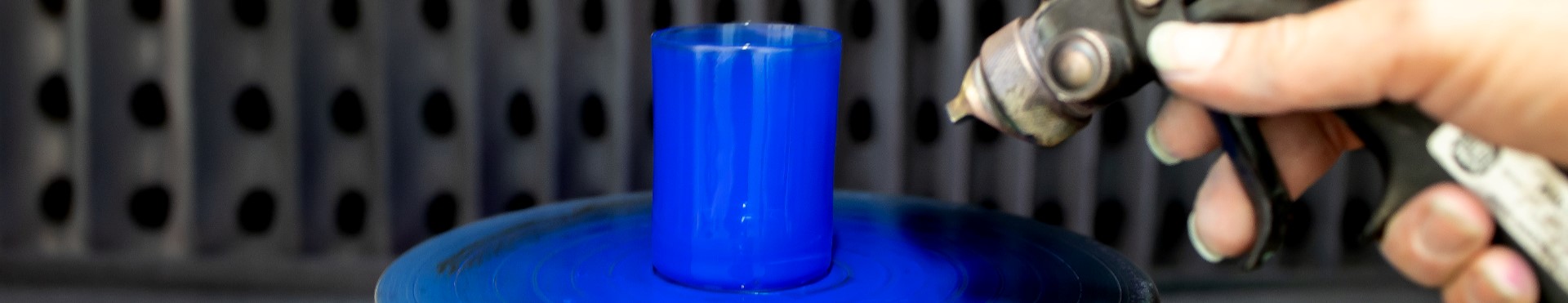

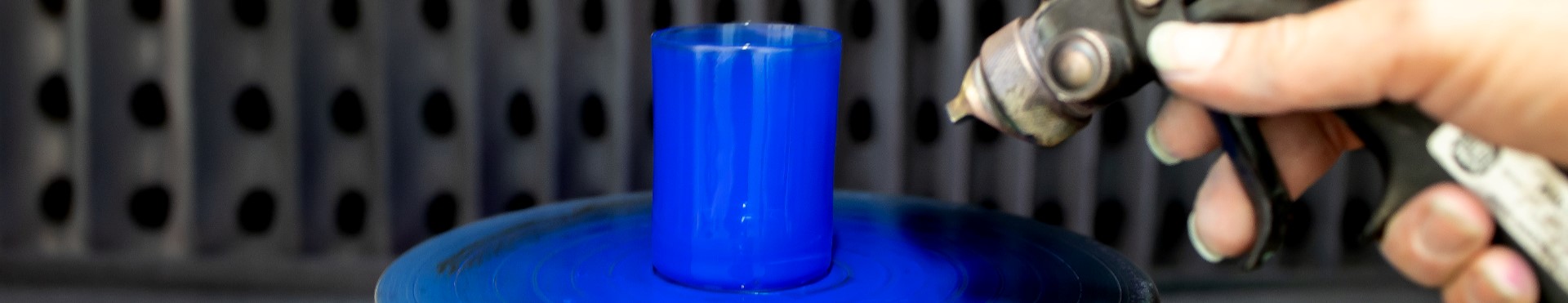

The extraction box - the design and size of the box depends on the product to be decorated. Also depending on whether the spraying will be manual or whether it will be a machine semi-automatic or fully automatic.

Spray gun - manual or automatic. Possibly with special attachments for internal spraying. Fitted with gravity feed or pressure tank for paint transport.

Selected spraying equipment can be tested in our GDS ACADEMY training centre.

The spraying area, like the paint preparation area, should be temperature stable all year round. This is the only way to achieve year-round consistent production (yes, the reason for this is to maintain a constant paint viscosity at a stable temperature).

Ad 5.) DRYING (FIRING)

In the case of organic paints (e.g. our HGC paints), the paints are dried at temperatures of 170-200 °C. At these temperatures, the paint becomes thicker and more resistant. Products that cannot be dried in this way for various reasons can be decorated with the HGC 3 series, where the crosslinking is guaranteed chemically and the temperature is only used to speed up the process.

The drying of the paints produces fumes which should be removed.

Ceramic paints are fired in kilns. Chamber, chamber or belt kilns. Flat glass is tempered in tempering furnaces. Before hardening, however, the paint must first be dried. For example in an IR drying tunnel.

Ad 6.) INSPECTION, PACKING (or preparation for further decoration)

After drying (firing), the product must be subjected to an output inspection. In addition to the visual inspection, we recommend that the organic paints are also tested for colour crosslinking (see. Our 3-part article on this topic ... HERE). The products are then packed or moved for further decoration.

CONCLUSIONS:

You can try out many of these issues in our training center.

Or sign up for our ORGANIC GLASS DECORATING BY SPRAYING course.

Ps: If we have forgotten something important, let us know.

+420 571 612 420

+420 571 612 420 gds@gds.cz

gds@gds.cz

EN

EN

CZ

CZ

hu

hu

bg

bg

Settings

Settings