The correct paint spraying procedure is the key to a smooth, spotless and uneven surface. In our guide you will learn how to prepare the glass, set up the spray gun and apply the paint for a professional and durable result.

Procedure

1. Clean the glass thoroughly. We recommend using alcohol-based cleaners such as ethanol or IPA to clean the glass. Acetone, thinners and petroleum-based substances are not recommended. Prepare the paint according to the instructions and filter through a fine sieve.

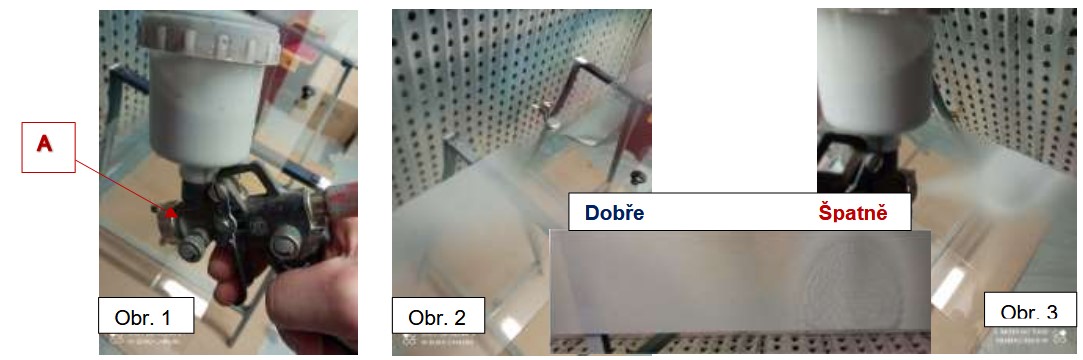

2. Prepare a spray gun with a 1.8-2.5 mm nozzle and adjust the beam for wide dispersion by turning the adjusting screw Fig. 1 (A) to the left. Fig. 2. This is an essential parameter for a good result, If the beam shape is too central, waves and spots will appear, see Fig. 3. Set the working pressure to 3-5 bar.

3. Spray evenly from left to right and back from approx. 30 cm at approx. 50% coverage, do not interrupt the beam when spraying, start and end approx. 5-10 cm behind the edge of the glass. The result should be a uniform surface without spots and slick areas (too much paint).

4. Allow the paint to wilt slightly on the surface (approx. 0.5-1.5 min. - depending on the ambient temperature) to allow the metallic pigments to set at different angles. The paint must not dry on the surface, as this would cause cracks caused by drying and shrinkage of subsequent layers of paint.

5. Spray the glass again in the same way as in point 3, but from top to bottom and back again.

6. Allow the paint to wilt slightly again as in step 4.

7. Depending on the type of gun used, the above procedure from the previous points must be repeated 2 to 4 times.

8. Once the spray is sufficient and even, it is necessary to cover it with 2-4 coats of paint to achieve the desired opacity. You can use the same metallic paint or choose another AQ2 series paint as the top coat. The important thing is not to let the surface dry completely in the meantime - the next coats are applied immediately, crosswise over each other, without waiting for any more to wilt. Properly executed, this procedure ensures a smooth and non-porous surface. If you stick to metallic paint only, the surface will be rougher.

9. Check the spraying by looking through the glass - no spots, ripples or any pigment clumps or other defects should be visible. The rougher and more porous the resulting surface, the lower the subsequent chemical resistance to adhesives and sealants. Based on our laboratory tests, we can recommend MAMUT SUPER CRYSTAL GLUE or neutral silicones for bonding glass painted in this way. However, the use of these and other adhesives should be checked internally.

Detailed procedures and practical demonstrations can be found in our seminar: How to paint flat glass.

If you have any further questions, please contact us at m.valasek@gds.cz or +420 734 756 669.

Article written by:

Martin Valášek

Flat glass, paints, UV adhesives

technical support, blasting systems

+420 571 612 420

+420 571 612 420 gds@gds.cz

gds@gds.cz

EN

EN

CZ

CZ

hu

hu

bg

bg

fr

fr

ro

ro

Settings

Settings